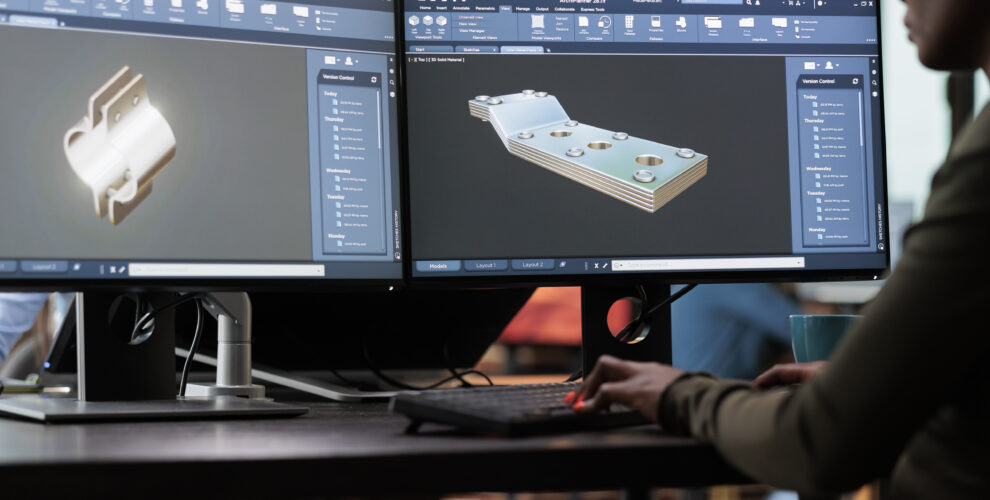

The manufacturing sector is being transformed by 3D printing, which is also altering how we create things. This revolutionary technology is making it easier and faster to bring ideas to life and is changing the way products are designed and made. Thus, today’s engineers need to ensure how 3D printing is making its influence in the manufacturing field or any other sector. However, the top engineering colleges in Coimbatore include additive manufacturing in their engineering courses; here you can find how it influences and its applications.

Why do you need 3D printing?

It is important for engineers to carefully evaluate the requirements of the project or client requirements to determine the most suitable approach. The following are the reasons why 3D printing is essential:

- Products can be made with a lot of precision and detail by combining modern printing methods with digital 3D design data.

- Manufacturers now have new options to create complex and individualized parts faster, at a lower cost, and with less waste.

- Manufacturers can speed up product development, cut costs, and use materials more effectively by utilizing this technology.

- 3D printing is altering the assembly business and permitting us to make items with exceptional speed and precision.

Engineers who pursue engineering at best engineering college in Coimbatore should understand and be aware of how 3D printing contributes to significant improvements in engineering and manufacturing. However, 3D printing has clearly transformed the field of engineering, enabling engineers to more effectively and creatively implement their plans.

How is 3D printing is transforming the manufacturing sector?

Traditional manufacturing processes like CNC milling and injection molding demand high upfront tooling costs. Manufacturers frequently demand high minimum order quantities in order to pay off tooling expenses across all units produced during a manufacturing process.

Using 3D printing, tooling costs are eliminated when manufacturing new or altered designs and products. 3D printing alters the business model for manufacturers and reduces risk as well as the cost structure because of its greater flexibility and lack of tooling. Let’s discuss this in detail.

- The manufacturing sector is being transformed by 3D printing, which has numerous advantages that allow for flexibility. It allows a product design team to speed up the production of a new product or design variation by eliminating tooling.

- A design can be sent to production and printed right away, as long as a 3D printer has enough capacity. Additionally, the product can be printed in multiple variants without retooling on the same machine.

- It can also enable businesses to reduce supplies and print things based on demand. Greater adaptability enables organizations to be flexible, respond to market developments more quickly, test different models, and gain access to the market more quickly.

- 3D printing can simplify the manufacturing process by reducing the number of steps required to produce a finished product.

- Before a prototype can be put into full-scale production, it may need to be redesigned. Companies can immediately print the finished product once the design is complete because there is no need for tooling and they can produce parts with simple to complex geometry using a variety of materials.

- Prototyping and production follow the same procedure, eliminating test runs that focus on replicating the prototype in a production setting.

- A design may need to be disassembled and reassembled for production using conventional manufacturing methods. Multiple parts that would normally need to be welded, bonded, or fastened together can now be made with 3D printing into a single finished product.

- This lessens gathering costs and can likewise give different advantages, like bringing down the heaviness of the completed item and disposing of expected joint disappointments.

- Practical models can likewise be utilized in the testing period of new items. Companies can also discover errors or flaws before ordering costly injection molding tools by having access to physical prototypes.

- Prototypes made with 3D printing are changing how products are designed. Many of the initiatives that are ignored today are a result of existing restrictions. With 3D printing, there are new chances to produce optimized items with innovative functionality and lightweight designs because design complexity is not a constraint in 3D printing.

- The lack of accuracy in 3D printing is a major drawback. Simple geometric shapes work best for the technology, which can result in inaccurate designs, poor fit and finish, and reduced durability. Manufacturers are developing new 3D printing technologies, such as multi-jet and high-precision printing, to overcome these limitations.

- So, engineers can work efficiently with this 3D printing. Secondly, markets now need to have experts who can mingle with these technologies. So, it is best for students who are taking internships during their final year in the top college in Coimbatore to have opportunities to work with market trends or be aware of how they have been utilized. However, improved product and design development, a shorter time to market, and lower production costs are all advantages of 3D printing.